I Nostri Punti di Forza

Esperienza e Competitività

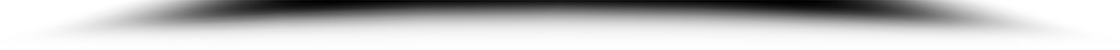

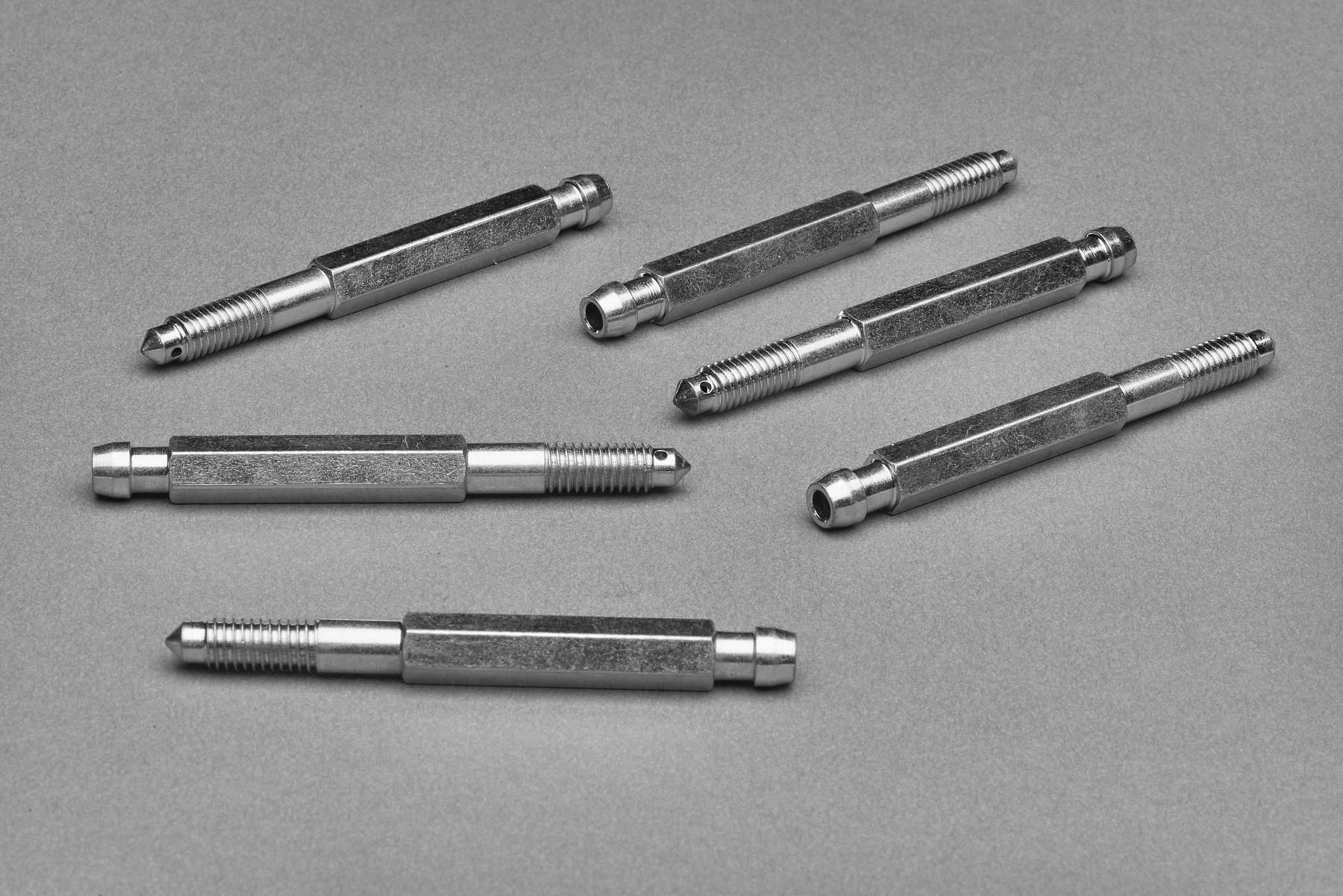

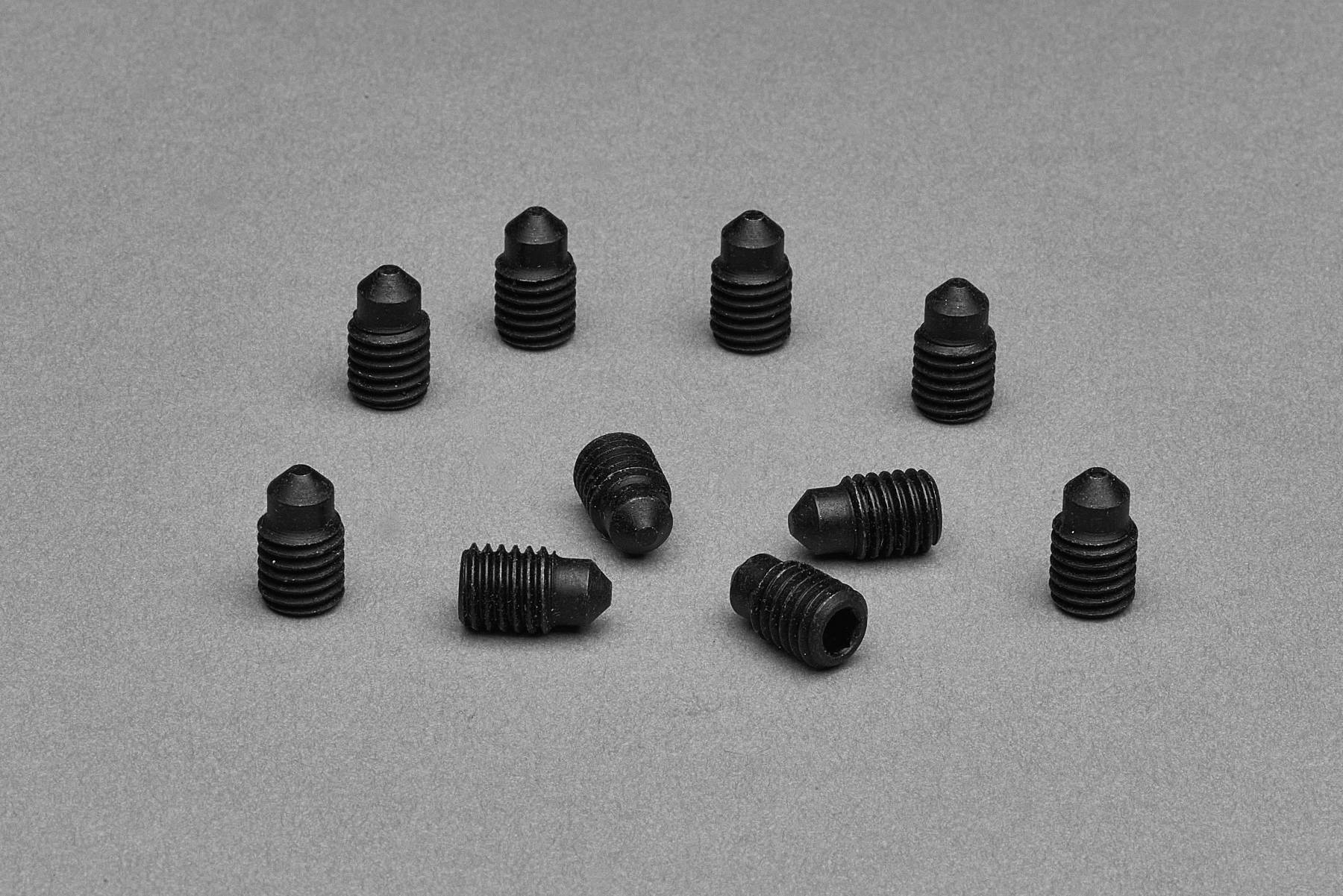

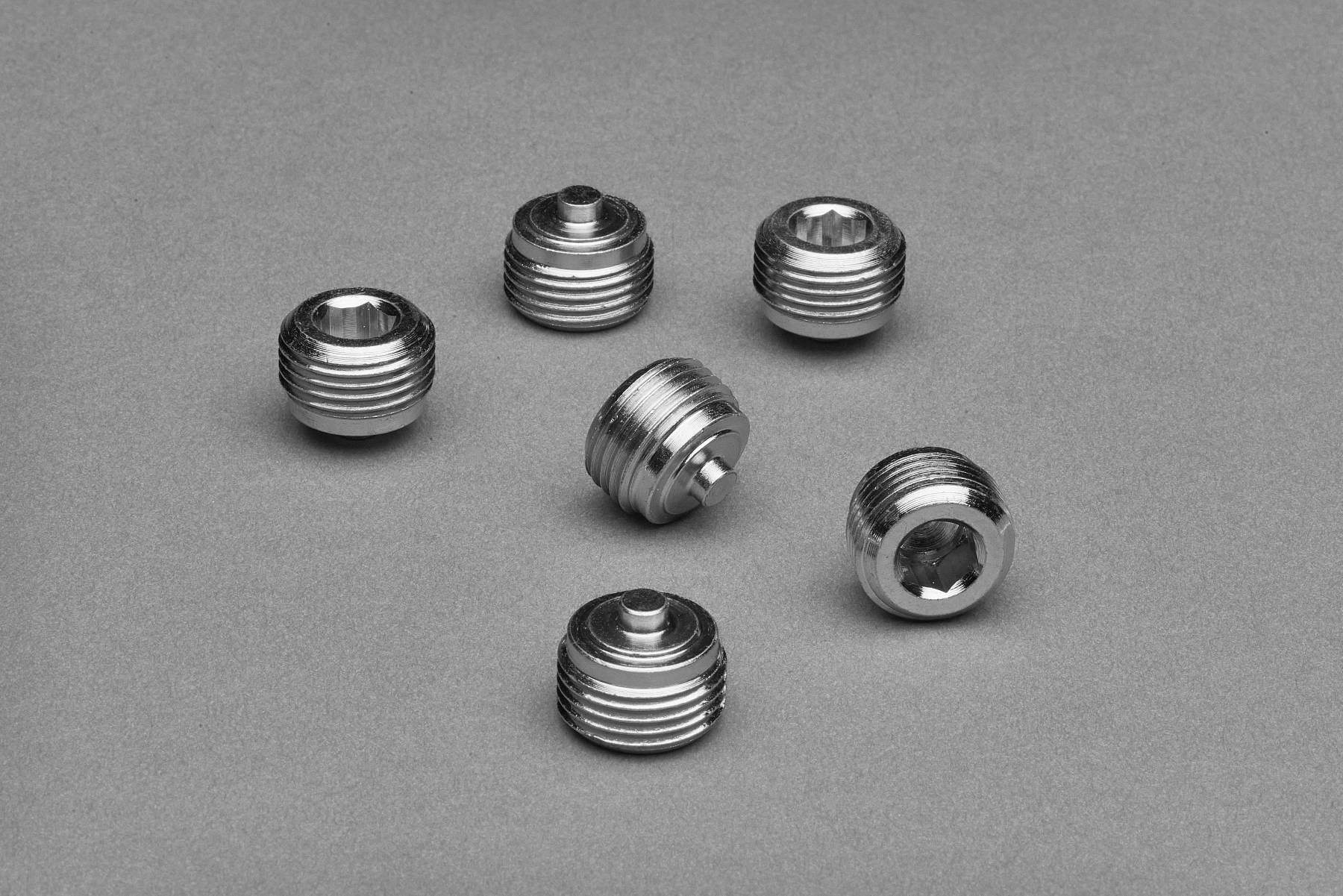

Tecnova, da 50 anni, garantisce efficienza e vantaggio competitivo nella produzione di componenti torniti

Efficienza e Flessibilità

Rapidità e flessibilità in ogni fase: dalla quotazione alla produzione, con soluzioni su misura e adattabilità a ogni esigenza

Innovazione e Sostenibilità

Innovazione responsabile, con etica solida e azioni concrete per un futuro a basse emissioni CO2

I Nostri Numeri

pezzi prodotti ogni anno

misure lavorabili

torni plurimandrino e CNC

codici attivi gestiti ogni anno

paesi serviti in tutto il mondo

personalizzazioni

Tecnova Srl

Via del Commercio 18

17038 Villanova d'Albenga (SV)

Italy